Precision Metal and Plastic Parts, Made Just for You

Sheet Metal Fabrication

CY boasts comprehensive sheet metal fabrication capabilities, enabling swift and efficient production of top-notch parts.

- Sheet metal thickness 0.5 - 10mm

- More than 10 kind of materials and finishes are available

- Fastest delivery time 3 working days

Start A Sheet Metal Quote

step | stp | stl | igs | iges | obj

All uploads are secure and confidential.

Type of Sheet Metal Fabrication

Under the umbrella term of sheet metal fabrication, various processing methods are employed to convert flat and thin metal sheets, not exceeding 0.25 inches in thickness, into high-quality parts suitable for their intended end use.

Laser Cutting

Sheet metal cutting is a process used to cut thin, flat pieces of metal into specific shapes and sizes.

Bending

Sheet metal bending is the process of using a machine to shape thin, flat sheets of metal into a desired form or shape.

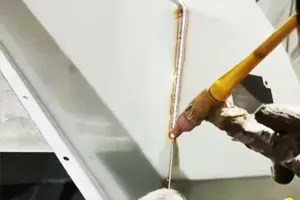

Welding

It is the process of joining two or more pieces of sheet metal together using heat and pressure to create a permanent bond.

Plasma Cutting

Looking for fast and precise metal cutting? Our advanced plasma cutting service gets the job done with unmatched efficiency and detail.

Punching

rom simple slots to complex patterns, our CNC punching service offers versatility and speed for all your fabrication needs.

Stamping

High precision. High volume. Our metal stamping service delivers consistent results for all your custom parts.

Our Advantages

Speed

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Quality

With multiple quality checks throughout the production process to ensure the final product meets your specifications.

Materials

We offers a wide variety of materials to choose from, including metals, plastics, and composites, to suit different applications.

Prototyping

We offers prototyping services, allowing you to test and refine your design before moving to full-scale production.

Sheet Metal Fabrication Capabilities

Our sheet metal fabrication service delivers industry-standard precision tolerances, ensuring reliable accuracy and a perfect fit for every component.

Maximum Dimensions

Max Diameter: 500mm or 19.7-in

Maxi Length: 1800mm or 70.9-in

Tolerances

Metal: +/- 0.005mm (+/-0.0002 in)

Plastic: +/-0.025mm(+/-0.001 in)

Minimum Wall Thickness

Metal: 0.5mm or 0.02 in

Plastic: 1.0mm or 0.04 in

Lead Time

4 bussiness days for most projects.

simple parts can be as fast as 1 day.

Design Guidelines

Optimize your designs for manufacturability with our expert guidance and feedback, ensuring superior results in sheet metal fabrication.

Aluminum: 0.5 mm – 6 mm Steel: 0.8 mm – 12 mm Keep consistent thickness across the part to avoid manufacturing complexity.

Sheet Thickness

Minimum inside bend radius: at least equal to the material thickness.

Avoid sharp corners — larger bend radii reduce risk of cracks and stress.Bend Radius

Minimum hole diameter: ≥ material thickness.

Distance between holes or from hole to edge: ≥ 2x material thickness.

Avoid placing holes too close to bends.Hole and Slot Design

Standard tolerance for features: ±0.2 mm (may vary by process and thickness).

Avoid overly tight tolerances unless critical.Tolerances

Add bend relief near bends to avoid tearing or deformation..

Relief depth should be greater than the bend radius.Bend Relief

Use corner reliefs to prevent tearing in internal corners after bending..

Use round or square reliefs depending on design.Corner Relief

Useful for self-alignment during assembly..

Ensure enough clearance (usually 0.1–0.2 mm) for easy fitting.Tabs and Slots

Design with welding, riveting, or bolting in mind..

Avoid interference with bends or formed features.Fasteners and Welding

Surface Finishes

Our sheet metal fabrication service delivers industry-standard precision tolerances, ensuring reliable accuracy and a perfect fit for every component.

| Name | Description | Materials | Color | Texture | More |

|---|---|---|---|---|---|

| Brushing | Brushing is a surface treatment technique that creates decorative lines on the workpiece by grinding the product, resulting in a beautiful and aesthetically appealing finish. | Aluminum, Brass, Stainless Steel, Steel, ABS,etc | N/A | Satin | |

| Sand Blast | Sandblasting is a method that uses high-speed sand flow to clean and roughen the surface of a product. It serves to achieve a specific level of cleanliness and varying roughness on the workpiece surface. | All Metal Materials, Plastic | N/A | Matte | |

| Tumbling | Tumbling is a surface treatment process where materials are placed in a rotating drum or container with abrasive media. The action of tumbling smoothens surfaces, deburrs edges, and improves uniformity. | All Materials | N/A | Smooth, Matte | |

| Polishing | Polishing is a mechanical surface treatment process that uses abrasives or buffing wheels to remove imperfections, smooth surfaces, and enhance the appearance of materials, leaving a shiny and reflective finish. | All Materials | N/A | Smooth | |

| Anodizing | Anodizing is a surface treatment for aluminum and its alloys. It forms a protective layer that boosts corrosion resistance, wear resistance, and hardness while changing the material’s surface appearance. | Aluminum, Titanium | Clear, Yellow, Green, Blue, Black, etc |

Smooth, matte finish. | |

| Painting | Attach the product to be sprayed onto the rotating bracket, and then secure the bracket on the assembly line. Apply the paint evenly to the product’s surface. This process enhances the product’s tactile feel, but it may be susceptible to scratches. | All Materials | Clear, Yellow, Green, Blue, Black, Multiple | Gloss, semi-gloss, flat, metallic, textured | |

| Black Oxide | Black oxide is an oxide film primarily utilized to enhance product corrosion resistance and appearance, while reducing light reflection. It is well-suited for treating steel and stainless steel surfaces. | Steel, Stainless Steel | Black | Smooth, matte | |

| Electroplating | Electroplating serves functional, decorative, and corrosion-related purposes, finding widespread use across various industries. For instance, the automotive sector often employs chrome-plating on steel automobile parts. | Aluminum, Steel, Stainless Steel | Gold, Silver, Nickel, Copper, Brass, Zinc, Chrome | Smooth, glossy finish | |

| Powder Coating | Powder coating is a technique for applying dry powder to metal surfaces, typically done electrostatically. The coated metal is then cured through heating or ultraviolet light to create a durable and attractive finish. | Aluminum, Stainless Steel, Steel,etc | Custom | Gloss, matte or semi-gloss | |

| Alodine | An alodine finish is a conversion coating applied to aluminum parts, creating a thin protective film that helps prevent corrosion. It also serves as a primer for further painting processes. | Aluminum, Stainess Steel | Clear, Gold | As machined | |

| Passivation | Passivation used on stainless steel to enhance corrosion resistance. It involves immersing the metal in an acid solution, removing contaminants, and forming a protective oxide layer on the surface, preventing rust and corrosion. | Stainess Steel | N/A | Matte | |

| Electroless Plating | Electroless plating is a chemical process depositing metal onto a substrate without an external electrical current. It involves a catalytic reaction between the substrate and a metal ion solution, creating a uniform and adherent coating. | Metal, Plastic | Gold, Silver, Nickel, Copper, Brass, Zinc, Chrome | Smooth, glossy finish |

Availabler materials

Our experienced professionals specialize in high-quality surface treatments to enhance the durability and appearance of your products.

Aluminum |

Stainless steel |

Cooper |

Mild Steel |

|---|---|---|---|

| 5052 | 304 | C110 | 1008 |

| 5754 | 316 | C102 | 1018 |

| 7075 | 316L | C103 | 1020 |

| 1060 | 410 | T2 | 1025 |

| 2A01 | 416L | H59 | 1045 |

| 5052 | 420 | H62 | Q235 |

| 5A05 | 430 | C1100 | Q345 |

| 5083 | 440 | SPHC | |

| 6061 | |||

| 7075 |