FAQ

CNC machining services

We provide CNC milling, CNC turning, 5-axis machining, EDM (Electrical Discharge Machining), and surface finishing services.

We cater to industries such as aerospace, automotive, medical, robotics, electronics, and industrial manufacturing.

Lead times vary based on complexity and quantity but typically range from 3 to 15 days. Expedited services are available upon request.

Yes, we provide anodizing, powder coating, polishing, bead blasting, electroplating, and other finishing options.

Yes, we specialize in rapid prototyping and low-to-medium volume production runs, ensuring fast turnaround times.

We can achieve tolerances as tight as ±0.01mm, depending on the material and design requirements.

Absolutely! We accept 2D drawings and 3D CAD files in formats such as STEP, IGES, and STL for precise manufacturing.

We follow strict quality control processes, including CMM (Coordinate Measuring Machine) inspection, visual checks, and dimensional verification.

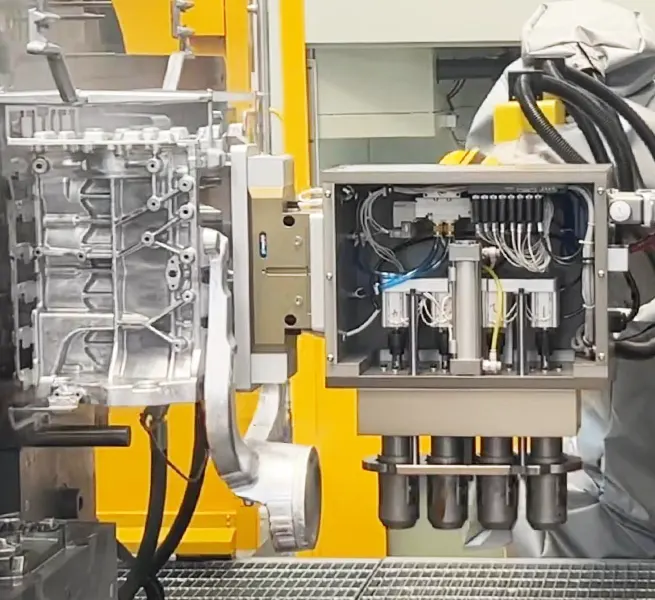

Die casting services

We primarily work with aluminum, zinc, and magnesium alloys, which offer excellent strength, durability, and lightweight properties.

High pressure die casting provides high dimensional accuracy, smooth surface finishes, fast production cycles, and cost-effectiveness for large-volume manufacturing.

Lead times vary based on project complexity and volume, but typically range from 2 to 6 weeks, including mold development and production.

We can achieve tight tolerances, typically around ±0.05mm, depending on the design and material used.

Yes, we provide CNC machining, surface finishing (anodizing, powder coating, plating, polishing), and assembly services.

While high pressure die casting is most cost-effective for mass production, we also support low-volume production with optimized tooling solutions.

Yes, we offer mold design, engineering consultation, and rapid tooling solutions to ensure high efficiency and precision.

Simply send us your 3D CAD files, material specifications, and production requirements, and we will provide a detailed quote within 24 hours.

Sheet Metal Fabrication

We provide cutting (laser, plasma, waterjet), bending, stamping, welding, forming, and assembly to meet different project needs.

Sheet metal fabrication allows for lightweight, durable, and cost-effective parts with high precision and quick production times.

Yes, we specialize in custom sheet metal parts and rapid prototyping, helping clients develop unique solutions quickly.

We can handle sheet sizes up to 4000mm × 2000mm, depending on material and cutting method.

Our services are widely used in industries such as robotics, medical devices, telecommunications, automotive, and industrial equipment.

Yes, we accommodate low-volume prototype orders as well as high-volume manufacturing with optimized production strategies.

Our sheet metal fabrication processes can achieve tolerances as tight as ±0.1mm, depending on the complexity and material.

We offer powder coating, anodizing, brushing, bead blasting, plating, and silk-screen printing for aesthetic and functional improvements.

You can send your design files in DXF, STEP, IGES, or PDF formats along with material and quantity details, and we will provide a quote within 24 hours.

Surface Treatment

We serve various industries, including aerospace, automotive, medical, electronics, and heavy machinery, ensuring high-performance coatings and treatments for metal components.

Yes, we provide eco-friendly coating and plating solutions that comply with environmental regulations, including RoHS and REACH standards.

Our treatments enhance corrosion resistance, wear protection, and adhesion properties, extending the lifespan of metal components in harsh environments.

Absolutely! We tailor our treatments, including thickness, finish type, and material compatibility, based on customer specifications.

We conduct rigorous quality inspections, including adhesion testing, corrosion resistance analysis, and thickness measurements, to ensure optimal results.

Yes, we accommodate both prototype projects and small production runs, allowing clients to test and refine their products before full-scale manufacturing.

Depending on the process, we can either enhance or reduce conductivity, making it suitable for applications like electronic shielding or insulation.

Yes, we offer specialized coatings that meet strict hygiene and safety standards required for medical devices and food processing equipment.

Turnaround time depends on the complexity of the process, order volume, and specific treatment requirements, but we strive for quick and efficient delivery.